Years of industry experience

Registered capital

Number of employees

Building area

Visit Weida Machinery

Jilin Weida Machinery Equipment Co., Ltd.

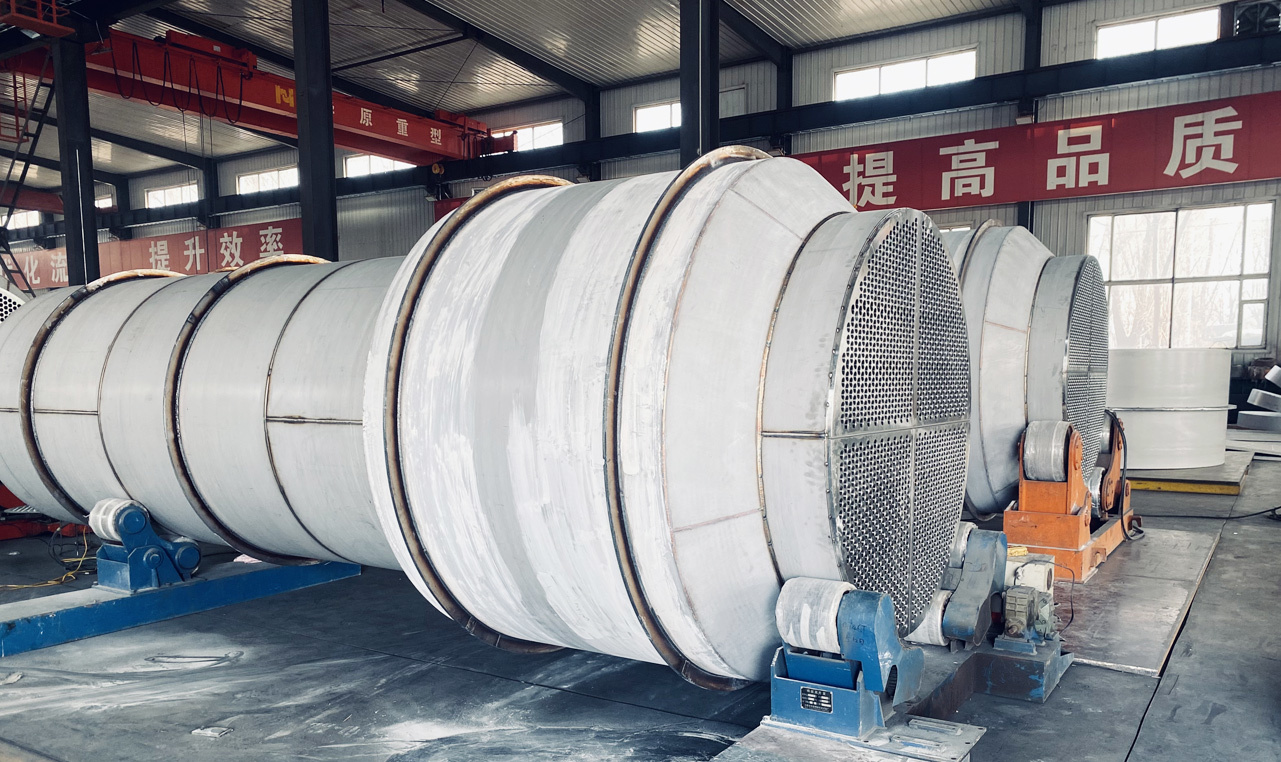

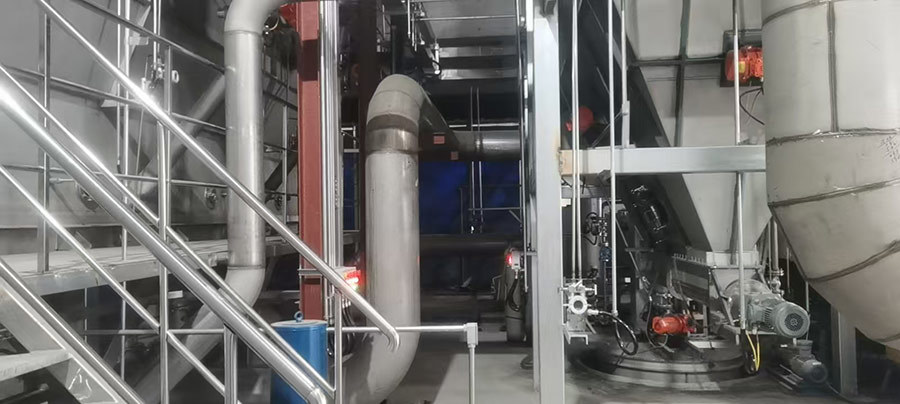

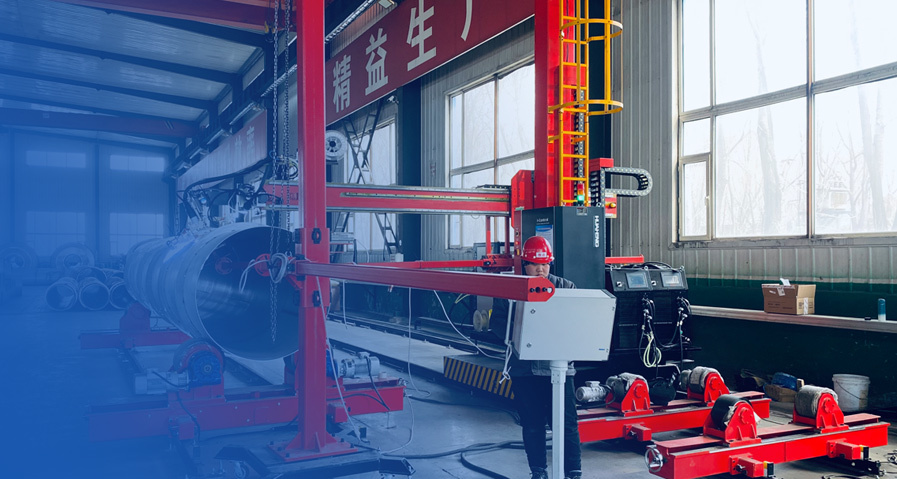

Jilin Weida Machinery Equipment Co., Ltd. was established in 2011 with a registered capital of 30 million yuan. It is located in the Green Garden Economic Development Zone of Changchun City, Jilin Province, which has a strong industrial foundation. As an engineering technology company integrating R&D, engineering design, equipment manufacturing, installation, commissioning and service, the company's production plant covers an area of 25,000 square meters. It currently has 105 employees, including more than 30 engineering and technical personnel and 6 senior designers. The company is equipped with professional mechanical processing equipment and testing instruments, uses mature manufacturing processes, and has established a standardized and perfect quality management system. At the same time, it has gathered a team of professional and technical personnel, actively using new technologies, new processes and new materials to comprehensively ensure the stability and reliability of products.

More →Industry layout

Food industry

The company's engineering and technical personnel have been deeply involved in the bio-fermentation industry for over 20 years, focusing on research and application of industry technologies. They have provided product production line design, commissioning, and operation management services to many starch and amino acid companies in China. Currently, the company has established a mature process technology development system, equipment design and manufacturing system, and customer service system.

Fermentation industry

The company's engineering and technical personnel have been deeply involved in the bio-fermentation industry for over 20 years, focusing on research and application of industry technologies. They have provided product production line design, commissioning, and operation management services to many starch and amino acid companies in China. Currently, the company has established a mature process technology development system, equipment design and manufacturing system, and customer service system.

Pharmaceutical industry

The company's engineering and technical personnel have been deeply involved in the bio-fermentation industry for over 20 years, focusing on research and application of industry technologies. They have provided product production line design, commissioning, and operation management services to many starch and amino acid companies in China. Currently, the company has established a mature process technology development system, equipment design and manufacturing system, and customer service system.

Chemical Industry

The company's engineering and technical personnel have been deeply involved in the bio-fermentation industry for over 20 years, focusing on research and application of industry technologies. They have provided product production line design, commissioning, and operation management services to many starch and amino acid companies in China. Currently, the company has established a mature process technology development system, equipment design and manufacturing system, and customer service system.

Feed industry

The company's engineering and technical personnel have been deeply involved in the bio-fermentation industry for over 20 years, focusing on research and application of industry technologies. They have provided product production line design, commissioning, and operation management services to many starch and amino acid companies in China. Currently, the company has established a mature process technology development system, equipment design and manufacturing system, and customer service system.

Success Cases

Technology R&D

The company's engineering and technical personnel have more than 20 years of experience in the bio-fermentation industry. The company has now formed a complete system of process technology development, equipment design and manufacturing, and customer service.

More content →

Strict quality management system

Committed to the research and application of cutting-edge technologies in the industry, it has designed, debugged, and managed product production lines for many large starch and amino acid enterprises in China.

More content →

Strict quality management

We have gathered a team of scientific and technological personnel with professional skills and rich experience, actively using new technologies, new processes and new materials to ensure the stability and reliability of products.

More content →

Our after-sales service

The company is equipped with professional mechanical processing equipment and testing instruments, adopts mature manufacturing processes, and has built a standardized and complete quality management system.

More content →Industry Partners

News Center

What are the key technical parameters of a multi-effect evaporator?

Key technical parameters of multi-effect evaporators include evaporation area, number of effects, steam consumption, feed flow rate and concentration, product concentration, and vacuum degree.

2025-04-21

How does an MVR evaporator treat wastewater with high ammonia nitrogen?

In treating high-ammonia wastewater, the Mechanical Vapor Re-compression (MVR) evaporator effectively removes ammonia nitrogen from the wastewater and recovers resources through a series of efficient evaporation and condensation processes.

2025-04-21

In accordance with the relevant requirements of the "Management Measures for Jilin Provincial Science and Technology Development Plan Projects" and the "Management Measures for Jilin Provincial Science and Technology Innovation Special Funds", the Provincial Department of Science and Technology has determined the list of proposed projects to be supported by the Jilin Provincial Science and Technology Development Plan in 2025, based on the project evaluation and demonstration situation.

2025-04-02

Improvement and innovation are our eternal theme

Multiple effect evaporation | MVR mechanical compression evaporation | Continuous crystallization | Spray granulation fluidized bed drying

Contact Now →